Car, Truck, Tractor and Marine carburettor rebuild and restoration from £195

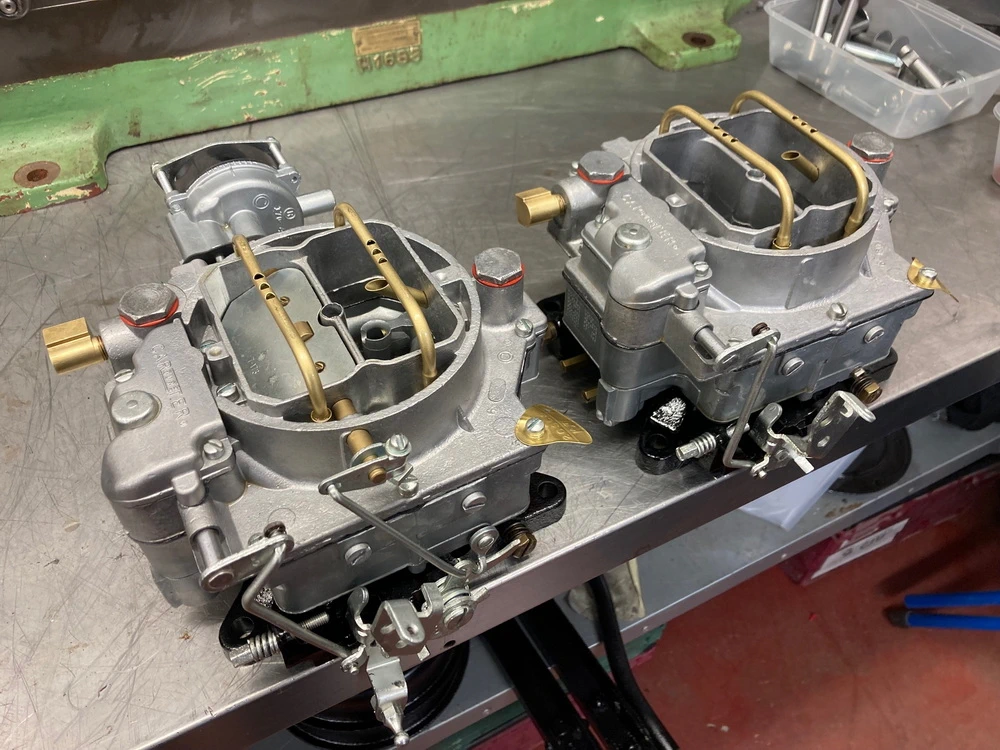

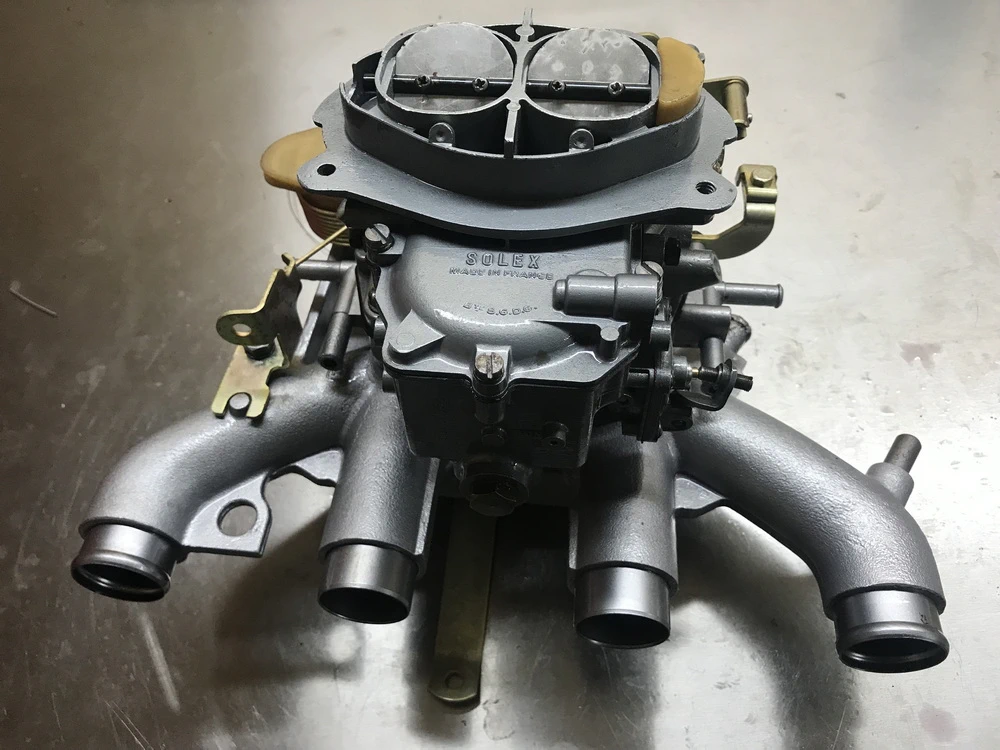

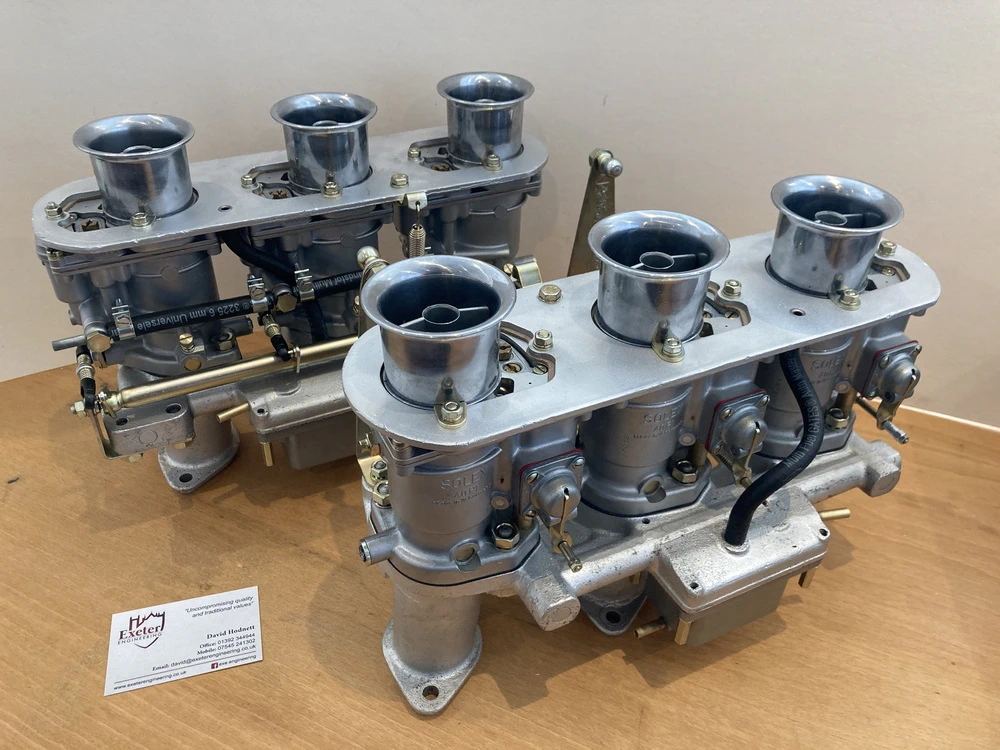

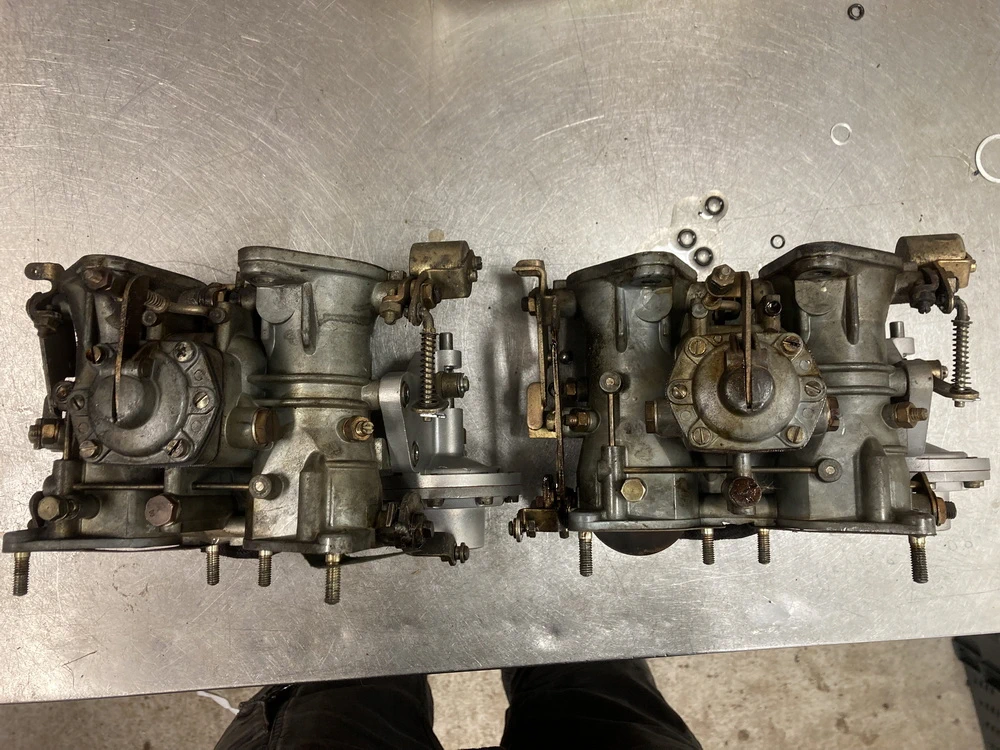

We deal with a huge range of types, makes and models of carbs, and offer two levels of service depending on the condition, application and finish desired.

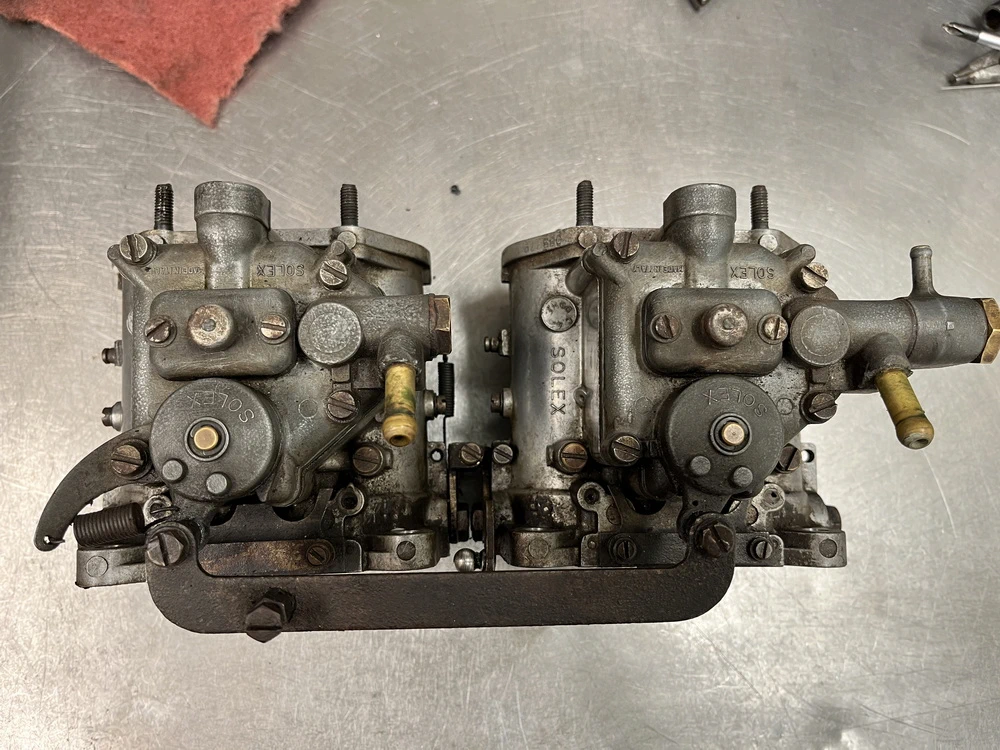

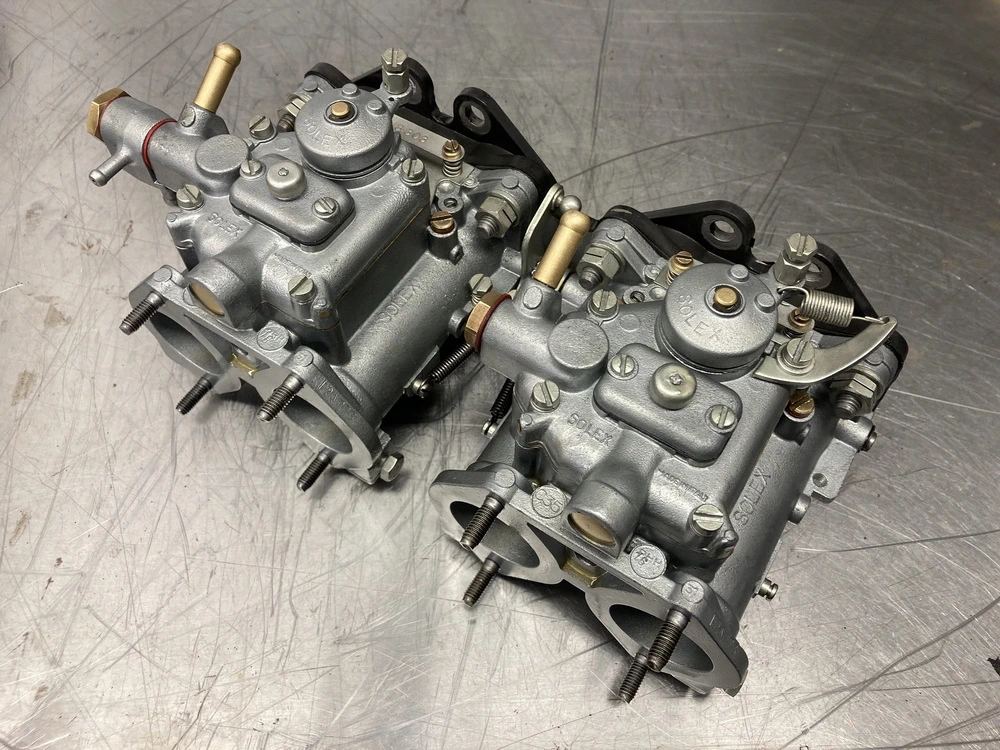

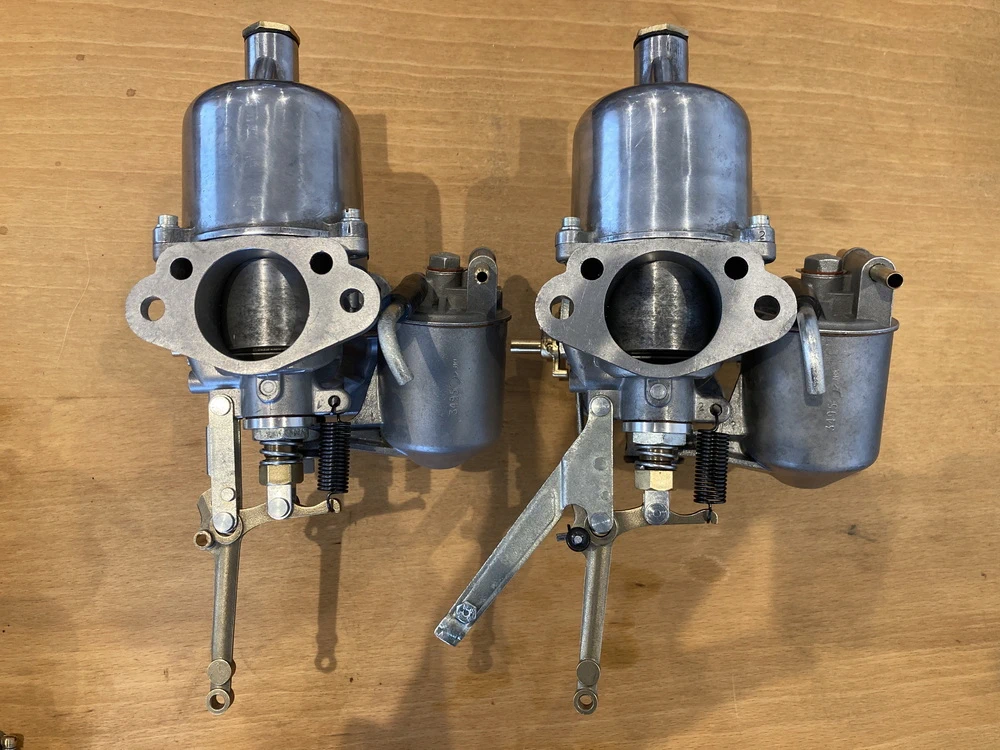

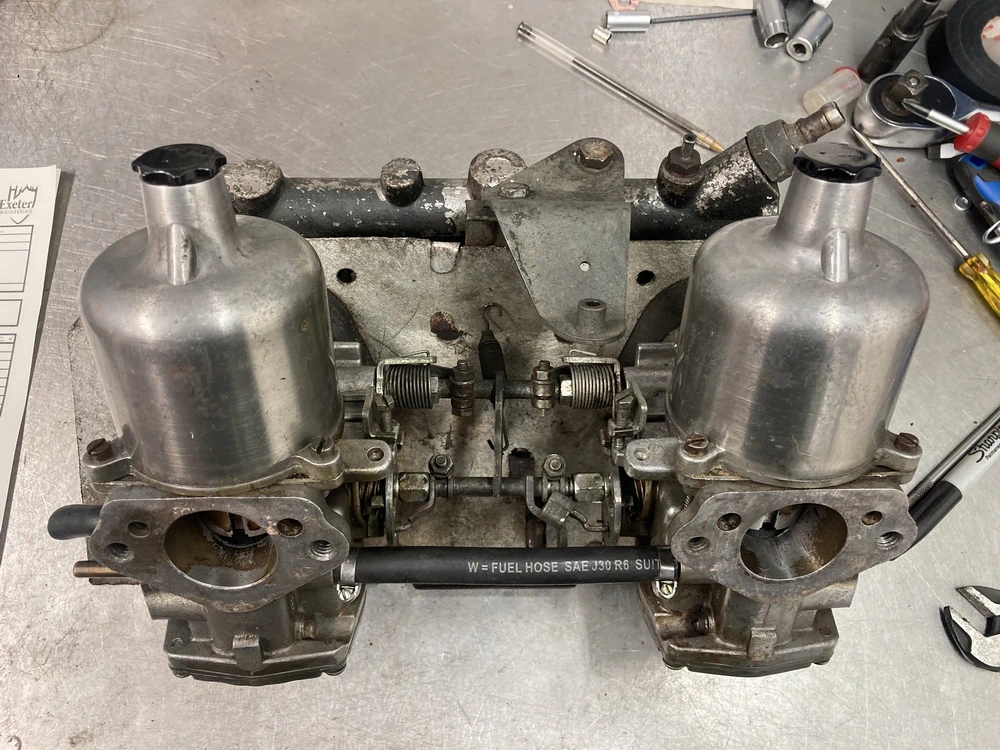

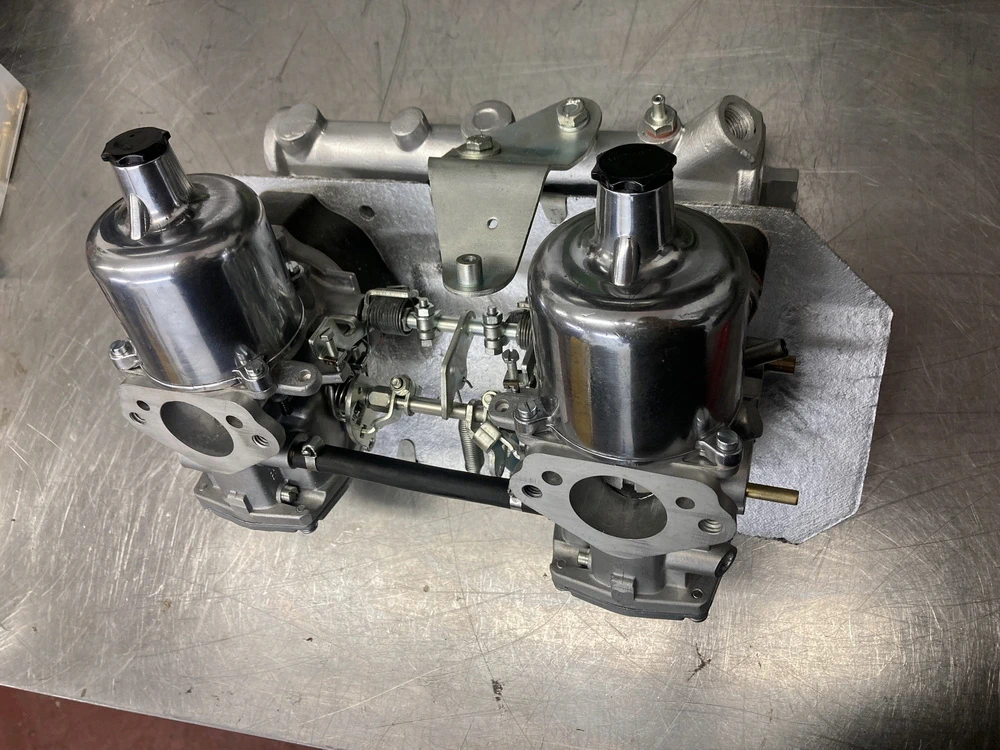

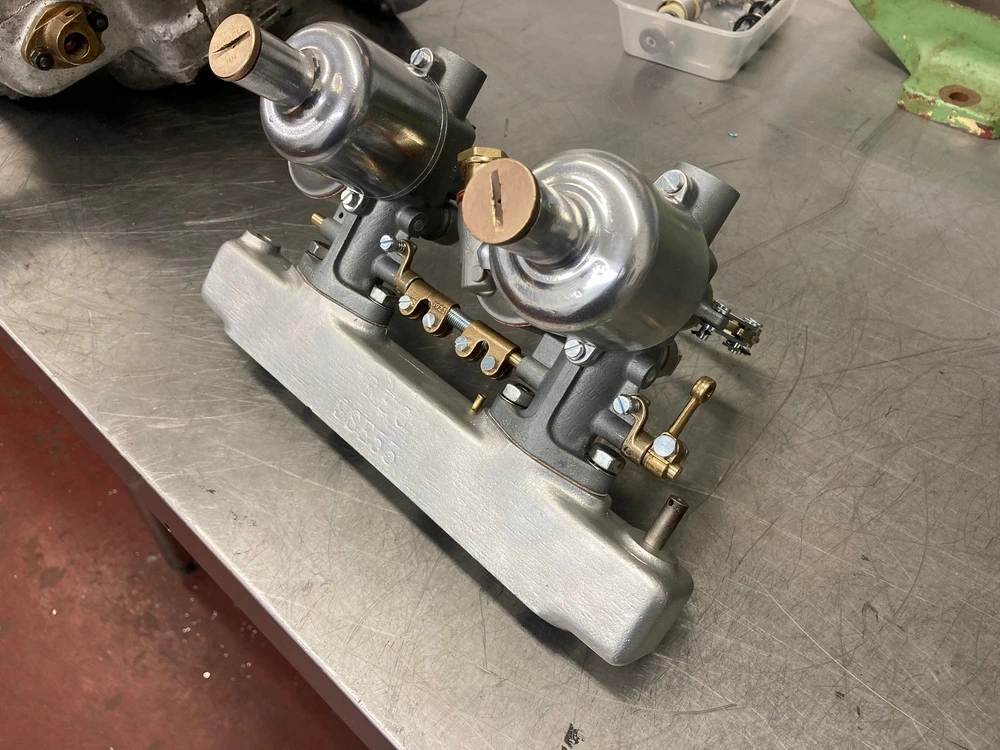

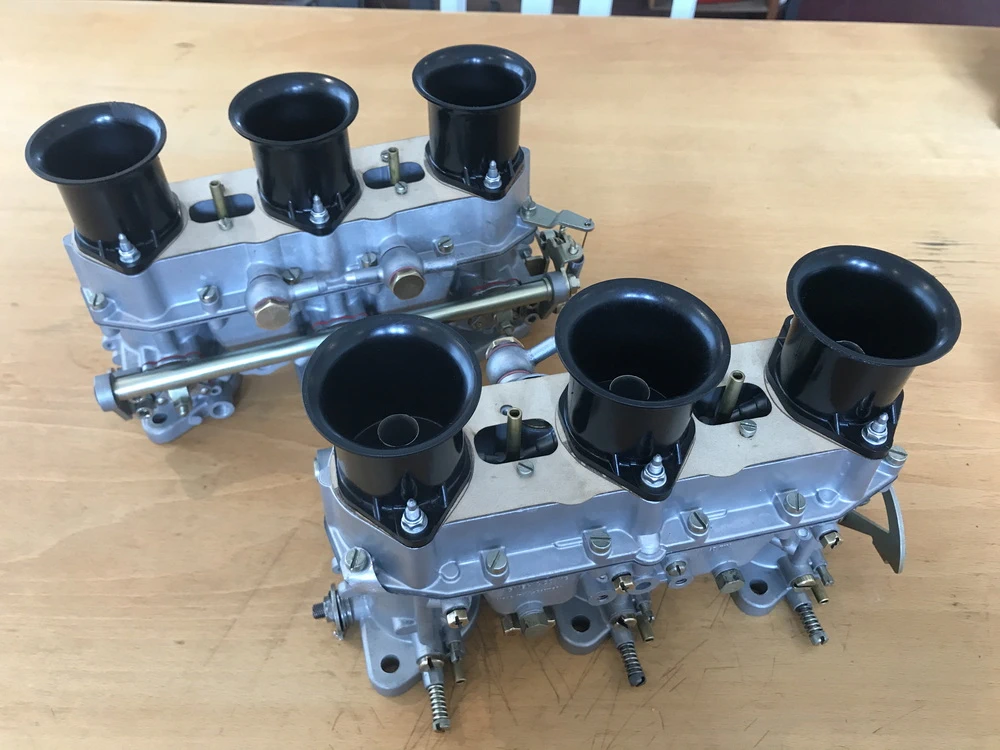

The standard service consists of a complete strip down, turning the unit into component form. All aluminium and brass components are then vapour blasted, flushed, then ultrasonic cleaned along with all fixings, linkages and internal components. The unit is then re-bushed/re-spindled (where applicable) all mating surfaces checked for true and machined where appropriate. All Jets and needles are checked and replaced as required. Perishables, wearing parts and gaskets are replaced as standard before the unit is then reassembled, tested and set up to allow for easy installation and further tuning. This service is perfect if you've got a worn or troublesome carburettor, that you want sprucing up and working properly again.

If you require a show finish and would like all the linkages electroplated, we can facilitate with two colour options of BZP: Silver, or Yellow/gold. We can also offer polishing of carb tops and components as required.

Should there be anything untoward, I.E stuck shafts, snapped screws, serious corrosion then we just charge an hourly rate of £60/hr to resolve after consultation with the customer.

Makes of carburettor we regularly work on:

SU, SOLEX, STROMBERG, ZENITH, AMAL, MIKUNI, KEIHIN, WEBER, DELLORTO, HITACHI, EDELBROCK, HOLLEY, VILLIERS, ROCHESTER, CARTER

For a detailed price and more information do head over to our contact us page, fill out the form with the carburettor and/or vehicle details and we'll get back to you as soon as we can!

Terms and Conditions:

Pricing and VAT.

Payment required on completion of service prior to delivery. Goods will be invoiced at time of dispatch, pricing may change, if absolutely necessary, without notification. Prices are in GBP and exclude Value Added Tax (VAT).

Delivery and collection.

Delivery is charged at cost. Dispatch is same day if receipt of payment is received by 12 noon. Delivery service is a next day service insured for the value of the service or other pre-agreed sum. Customers may collect, or deliver during our normal business hours. No appointment is necessary.

Damages and Non Delivery.

In the event of discrepancy, or damage in transit, it is essential to sign the carriers delivery note “contents unexamined, casing damaged”. Examine the items in question and inform the carriers and ourselves of and shortage or damage within 3 working days of delivery confirmation. Customers are responsible for advising us of the non-delivery of goods within 10 working days of invoice, following which no claims can be pursued.

Returns, Warranty and Liability.

Exeter Engineering Solutions Ltd refurbish carburettors on a “best endeavours” basis. We can make no guarantee that the original functionality or cosmetic specification of these aging parts can be perfectly met. We will of-course make our best effort to evaluate the viability of each unit upon strip down, from here we can advise on any issues found and any price fluctuations likely to occur prior to proceeding with the rebuild process. The Customer is paying for a service as apposed to a new product. Should a new product be available and more cost effective then we will offer this as a solution.

Should the refurbished carburettors not perform as expected we will endeavour to rectify without additional charges. Please read the taking delivery and installation section as this may resolve your issues! Customers are required to contact us prior to retuning goods to enable us to determine and discuss the nature of the issues.

Exeter Engineering Solutions Ltd is not responsible for losses, damage or injury of any kind as a result of failing components or design of carburettors. Exeter Engineering take every precaution to make sure carburettors are leak free prior to dispatch with every carb being leak tested. However, the customer is responsible in making sure that there are no fuel leaks, prior to and after installation. We make the assumption that carburettors and associated parts are being removed/installed/set-up by knowledgable and competent people. The potential for fuel leaks, fire/explosion and engine damage make these parts very safety critical and therefore not suitable for handling by the un-initiated. Exeter Engineering will take no responsibility for engine damage caused by the failure of the customer/mechanic to ensure correct fuel mixtures at all operating conditions before use.

Taking delivery, installation of your refurbished carburettors.

Carburettors are highly refined and calibrated fuel metering devices and should be fitted and tuned by qualified personnel. All makes and models require care when handing and should be fitted in clean dirt/debris free environment. Where a carburettor has a mating flange to the manifold a gasket will be supplied to enable easy installation. Make sure both flanges are clean, flat and free of debris. Do not use RTV or a sealing compound unless otherwise advised. Do not over tighten fasteners as this can cause warping of flanges. Always fit a clean, paper element fuel filter during installation. Make sure fuel is fresh (no older than 30 days). If once fitted and the fuel tap/pump turned on, the carburettor overflows, give the carburettor a light tap, on occasion the needle valves just need re-seating after transport. Should the issue persist, contact us.